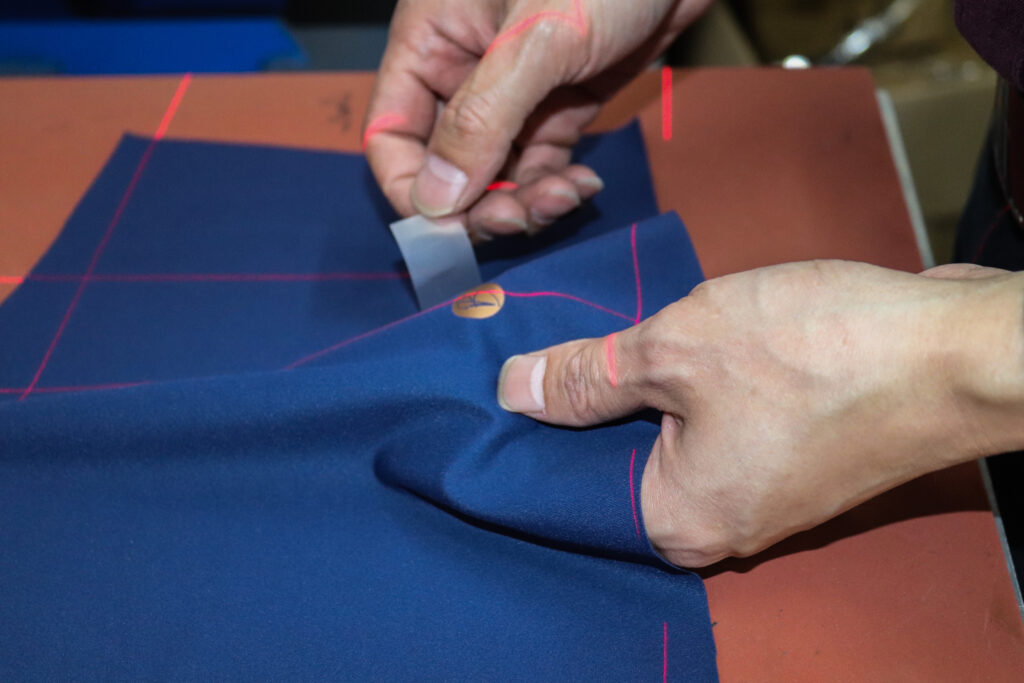

Quality control is a critical step in the process of manufacturing.

Our quality management system covers Supplier quality assurance, IQC, In-process quality control, final quality control, OQC and full Inspection before shipment.

It means that Comfy&Vitality always make quality a top priority.

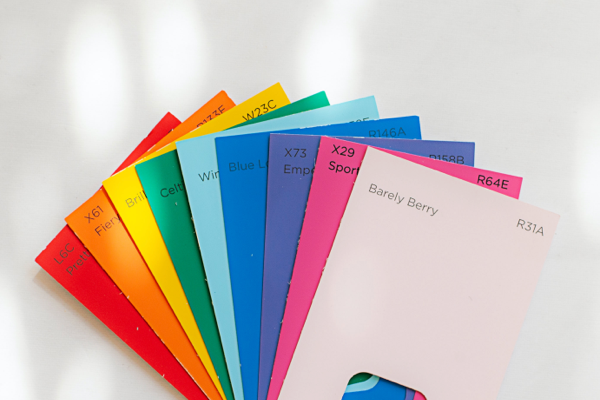

By strict quality management, we prevent product defects run through the whole production process-from raw materials inspection to delivery.We ensure you have a high quality of product, if there a product fails inspection, it will back for reprocessing.